To 3PL or not to 3PL, that is the question. Third Party Logistics (3PL) has grown tremendously in recent years, mirroring a dynamic and ever-growing e-Commerce market. Whilst 3PL fulfilment can be a godsend for a growing business, it is not a one-size-fits-all solution and many businesses question whether out-sourcing such a critical component of an online business is really the right choice. Given that this decision is usually made by retailers planning for substantial growth, making the wrong choice can have a devastating impact.

Learn from two extremely successful online retailers, St Frock and GoLights who have made the decision to in-source what they believe is the core operation of their business.

What follows is a full transcript of the webinar. If you’re short for time, skip straight to Panel Introductions, or read on for five key take-aways:

The Outlook: When it comes to logistics and fulfilment, the experience of new generation retailers is limited. In the days of larger, sort of omni-channel retailers, logistics is the backbone of their business. The focus of the next breed of retailers is on growing and curating a brand, creating an experience for their customers, and on channels like social media to create a successful business.

A Core Operation: Fulfilment can be termed, the “core” of any online business. Whether a retailer makes it or not, really comes down to these three critical areas in fulfilment: stock availability, dispatch speed and shipping speed.

The Benefits: The key logical benefits when it comes to outsourcing to a 3PL include, network efficiencies, scalability, flexibility and being able to tap into logistics expertise and best practices. These work very nicely for retailers who potentially have a simplified product range.

Not A One-Size-Fits-All Solution: There are some nuances and complexities around retailers that would really be a challenge for any third party logistics providers to even be able to modify their processes to service them, without adding costs to their own business as well.

Tips On Getting 3PL Right: On how to do 3PL right, it’s important to see if their other clients have similar products and business sizes, having a testing period and being clear on obligations and expectations for an exit plan if things don’t work out.

Read the full transcript below.

Introduction

Rob Hango-Zada: A big welcome to everybody who’s joined the webinar. Please be gentle on us, it’s our very first webinar. It feels like a backroom production, but we’ve got plants and we’ve got people, so we’re good to go, I guess.

We’ve got a good mix of people on the line. So we do have telco providers, we’ve got retailers, we’ve got solution providers, and a really broad array of attendees. So, you know, I think what James touched a point was, this is a really critical point for a lot of retailers. There’s not a lot of experience that new generation retailers have with logistics and fulfilment. If you think about the days of larger, sort of omni-channel retailers, logistics is the backbone of their business. If you think about it, new generation, new breed of retailers, their focus is on growing and curating a brand, creating an experience for their customers, and focusing on avenues like social media and the like to really create a successful business.

So the whole reason that Shippit exists, and the whole reason that we’re having this webinar today is to really empower retailers to make the right decisions for their business, and to also help them empower them through the journey of creating successful empires themselves. So I’m really thankful to have both Sandradee and Nick in the call today, and I think you’ll learn a great deal from their experiences. So without further ado, I guess, you know, any webinar is only so good as what you can take away from it, so I’ve been very practical and tactical. What I think you can get out of today is really understand the importance of the fulfilment process on your customer, and your business.

Secondly, really about the key benefits of keeping fulfilment operations in-house. There’s a lot of education in the market about the benefits of taking fulfilment out to a 3PL provider that not a lot for the case of, are keeping internally. And it can be a really big black box for a lot of people. So we’ll really like to take the lead on that and understand it a bit further. Also, how to set your business up for success if you do decide to go the route of in-house fulfilment.

And then of course, you know, there are some remarkable partnerships in markets between 3PLs and retailers. And it really is about making the right partnership stick, and that works for anything in the logistic side, partnering with the right carrier is critically important to represent your brand, just as much as it is partnering with the right email provider, partnering with the right website provider, whoever it may be.

So just collecting some tips from, I guess, those that are with us, and then even extending that to those that are on the call with their experiences too. So we’ll talk you through how to choose the right 3PL provider for your business as well. Keeping it nice and open.

Webinar Structure

So the way that we’ll structure the webinar is with three key modules. The first is really explaining why fulfilment is a core activity, and kind of talk a bit about what core activities really are. Secondly, we’ll move to the case for 3PL, you know, and what considerations come to mind and why a business would choose to outsource. And then we’ll come to learning from both St. Frock and Go Lights who have experienced a 3PL type of fulfilment relationship, and have also experienced the other side of the coin of owning that fulfilment journey in-house as well.

So there will be a panel discussion, we’ll go through a few questions there, and then what we’ll do is we’ll flip it over to the audience for a bit of excitement. You know, I’ll try and do my best as a panel, kind of moderate a bit. Obviously I’m no Paul Greenberg, but please bear with me.

Fulfilment As a Core Activity

So to kick things off with understanding fulfilment as a core activity. So no doubt, if you’re an online retailer, fulfilment’s critically important to you. Making the sale is a difficult journey, driving conversion to your website, having the right product mix, all those are critically important to achieving your kind of success with the customer base. But really, the rubber doesn’t hit the road until you get to the, what we call the “arse end” of eCommerce, which is the logistics space. And that’s getting the products to the customer’s hands.

So let’s go on a bit of a journey before we get stuck into things, you know. If you’re somebody with an idea and you’re sitting at home thinking, “You know what? It’d be great if I could start selling candles online.” You know, you start your business, you start looking for suppliers, you start thinking about how you can construct this, how you could style it, what the brand could represent to your customer. You may launch on eBay store, you maybe launch market stalls to test the product fit. The product seems to work, people are talking about your product, it starts to grow. As time progresses, your business starts to gain momentum. Now, you’re starting to stare down the barrel of what could consequently become a really large business, but you’ve got to make the right decisions.

That is where it’s quite important to start thinking about your fulfilment. So what used to work for you as a little hobby, now probably knowing what works for you, so storing things in your garage, you’re probably starting to outgrow that. You know, finding the right office space, which is a mix of office people and product, and you’re now tripping over products in your office. How do you take that and how do you turn that into a scalable business to the photos that you see, the likes of the Catch Group, the likes of Amazon, even. And you think about those types of warehouses. How do you make that leap and how do you prepare for it?

The other question is, at what point in time do you do it? Because you kind of got to build the plane while it’s in flight, so I think those are the types of considerations that people come to us with looking for a solution on. And this is exactly what the experience of both St. Frock and GoLights have kind of gone through.

Critically, what we find is that sustaining growth lies in three core areas. So if you could really think about logIStics, you know, fully modern business for new retail, as it’s kind of framed in the newer language. You know, it’s about three critical things. The first is about stock availability. So selling stock online is terrific, if you don’t have the stock to fulfil that order, I think you’re in a little bit of a mess.

Second piece is about dispatch speed, and this is what separates good retailers from bad retailers. Getting products out to customers and in an efficient manner, not taking too long to get products from the time an order has been placed to the time the carrier picks it up. So, you know, based on all the retailers that ship through our platform, on average, 25% of the total time it takes the delivery to get from order placed to completed status, is sitting in the dispatching progress piece. So if you think about that, a quarter of the time that customer is waiting is due to the business’ ability to get a product out.

Three-quarters, however, sits with the carrier, so that brings me critically to the next point, which is shipping speed. And shipping speed is quite important. You know, today, driving conversions from online sales is really rested in standard deliver. But, you know, the expectation of the modern consumer is, you know, fast delivery, different delivery options, you know, what about same day, how do you enable that? What about next day, how do you enable that? And what about even faster options that matter as we start as we look into the future, with a lot of innovations that’s happening, the point-to-point delivery space as well.

So critically, you know, whether you’re going to make it or not really comes down to these three critical areas in fulfilment. And this is what we term the “core” of any online business. I think if you’ve ever heard any really successful online retailers speak, they always talk about this fact that they’re a logistics business first, and then whatever product they sell is second. John, when he talks about this all the time, you know, there are logistics businesses who happens to sell fridges. And at the same way we’ve got a logistics business that happens to sell dresses, and a logistics business that happens to sell lighting.

So what are the consequences of getting it wrong? We talk a lot about conversion when it comes to the online sale, but we don’t talk a hell of a lot about retention. All the things we talk about here at Shippit is, “What types of activities do drive retention?” And once there’s been a bit of research on it, nobody’s got the hard and fast facts on what actually happens to bad delivery experiences.

If you’re an online retailer, you’re probably pretty familiar with customer complaints. But there’s only a small fraction of customers who ever actually complain. the majority of which who have a bad experience will never complain, or simply silently slip away into the dark and not purchase again. So lifting the lid on that, what we do find is a negative delivery experience, or a negative fulfilment experience results in about two-thirds of all those customers who have that bad experience vow never to buy from your brand again. Two-thirds. Just think about the cost of acquisition, how much time you spent curating your product mix, how much time you spent crafting your brand, only to leave it in the hands of a carrier provider, who results in a negative delivery experience.

So that’s something that’s really critical to understand here. And then, you know, with the age of social media, I don’t need to say it when they have a negative experience, they jump on Twitter, they jump on your Facebook page. You know, they leave Google reviews about the product and brand experience itself, and it can really tarnish your brand. So these are really critical things to get right when it comes to the right partners in the fulfilment journey.

So how important is fulfilment on the customer experience? Take Jeff Bezos, right? I’m sure it’s not the first time that somebody’s talked about Amazon and how they fulfil and all that sort of stuff. But a little-known fact, or I guess something that’s coming to light a lot more prevalently lately is that Amazon actually own end-to-end logistics process to truly delight the customer. So I think last year they took a lease out on 20 Boeing 747s to cross the nation of America to deliver their products, to hit their two-day shipping promise. And you know, they own their warehouses, they own the logistics network. They’re really closing the loop on what is that customer transaction. That’s how important fulfilment is to Amazon. So if we could kind of take a leaf out of their book and understand what they do well, there’s so much material out there that if you read up on it, it comes down to three critical things in their warehouse.

So there’s a lot of philosophy around a customer-experienced focused warehouse. Amazon’s a big proponent of customer experience, because that’s what keeps customers coming back.

So the first thing that I have in every warehouse is s traffic lights system on every SKU that they carry. So what that traffic lights system does is it tells them when stock levels are critically low. So touching on that core capability of stock availability, if an item enters that red zone more than once, if anyone’s familiar with Six Sigma, they jump into a Kaizen process. Kaizen workshop, which basically identifies how they can prevent that root cause from ever happening again. So they’re actively working on a daily basis to minimise their out of stocks.

Secondly, their warehouse is organised by a random array of product. So pickers are able to actually put new stock into different areas within the warehouse, and what that does is it speeds up the efficiency of their packing process. So any smaller retailer who’s probably tuned in today, you’re probably looking at your stock room, or your warehouse right now, and you’re thinking, “How do I arrange all of these different products to enable picking inefficiency?”

There was a bit of a YouTube video that kind of came out a little while ago about Amazon’s served bananas next to milk, next to laundry detergent, and why that is the case in some of their dark stores. And that really is because it speeds up the picking efficiency for any pick-up. There’s a bit of science behind that.

And the third piece is a two-day shipping guarantee. So it’s not two days for a carrier to get a product from Amazon to the customer. That’s two days from the time that order is placed to the time it arrives on the doorstep of the customer. So if you could take anything away from Amazon and the way that they’re looking at the market, and the way that they’re going after customers, it’s about maintaining focus on those three core areas by looking at it from a customer’s viewpoint.

If you haven’t yet, go out and get this book, “Delivering Happiness,” which is Zappos, for those that don’t know, Zappos is the world’s largest footwear retailer. So a massive proponent, particularly Tony, the CEO of Zappos and founder, is a big proponent of delivering happiness and about the customer experience. So they talk a lot about the core, and a lot about what the core is to run my business. And they say critically, “Never outsource your core component.” They’ve got a very strong view and, that’s kind of, reading about this story will help you understand why, but they also view call centers, keeping them in-house is critically important. And rather than burying your contact number, kicking it on the forehead of every employee and the forehead of every customer so that anyone can look in the mirror and give them a call. That might scare the pants off a lot of online retailers because that means you’re not actually limiting the number of calls you get, you’re actually increasing them. But they thrive on that, they see that as core to their innovation, the same way that they view warehousing as core to their innovation as well. So if you haven’t yet, go out and get this book, it’s fantastic.

So I hope that kind of frames up fulfilment as a core activity for any online business. Now what I want to dive into is the case for 3PLs. So I guess the deciding factors as to why you’d want to move into a 3PL, or choose to change your fulfilment practices.

The Case For 3PL

So any literature will kind of show this very clearly, and there are some key logical benefits when it comes to outsourcing to a 3PL, and these work very nicely for retailers who potentially have a simplified product range, or have found the right path.

The first thing is network efficiencies. So traditionally, if you think about logistics space, it’s all about throughput and all about economies of scale. So as a small retailer, how do you tap into those efficiencies in a sustainable fashion, and in a way that you don’t have to have the massive amount of business to do that? So it’s about optimising space so you don’t have to go on and sign a big lease on a massive warehouse that you can potentially grow into one day. But you can tap into the space that already exists. How do you tap into high-frequency shipping relationships so you can get better rates? How do you hire staff and scale up staffing quickly? How do you get the right pallet racking? How do you get the right facilities and infrastructure inside that warehouse? So that’s really the bread and butter of the 3PL, and that is the core reason why it’s a strength of a proper third party logistics warehouse.

Second piece is about saving time and money. So, you know, the theory is that when it’s your core business, you should get sort of the fulfilment piece right day in, day out, then you don’t have to waste your time trying to figure out things that have already been solved by others. So reducing your time and energy and money spent on running a warehouse is another core business.

The third one is about expertise in logistics. So logistics is really a tricky space, and traditionally, you’d need a PhD to really figure things out in the logistics space, but it’s all in the name and logistics is quite a logical business. And 3PL providers certainly have that worked out because they run a tight ship. It’s a very difficult space to be in, along with shipping providers, it really is where the pressure and the rubber starts hitting the road, so having the right expert is really critically important. And many 3PLs do this very well.

Scalability and flexibility. So if you happen to have a sales spike and you need to start bringing in more stock, where are you going to put it? 3PLs have enough space to be able to move things around, and with the right seasonal mix of the clients, some clients will contract, while other clients will expand, and they’ll fit nicely within a shared warehouse environment.

And the fifth piece is, obviously, being the bread and butter of that business, they’ll continually improve. So their picking practices will get better, their shipping practices will get better, their warehousing operations will get better, always improving and focused on those best in class practices.

Now, in most cases, this works quite well, but for some businesses it may not work at all. So in the case of Zappos, for example, they’re decision for bringing it in-house, it’s really because they found they had a quite complex business, and they really needed to be as close as possible to their stock. And there’s an underlying current at times where you may feel that a 3PL’s focused more on efficiency, whereas you as a business owner is more about the customer experience. Think about handwritten cards, and you know, the time you’ll take to pack an item. Some 3PLs can actually do that whilst others will choose not to and simplify that journey. So this again comes back to finding the right partner because they could at times be competing priorities that do exist. But obviously the more complex the business, and the greater the focus on being closer to the product, is kind of building the case to more or less keep that service and experience in-house.

Panel Introductions

So at this point I’m going to invite the guys from St. Frock and GoLights to share their experiences, so we’ll shuffle in as we can. I’ll get them to talk to you about their journey as well.

So, Nick, you’re free to come on in, buddy. Say hello to the people waiting at home.

Sandradee Makejev: Hi!

Nick Nicolaou: Hello.

Rob Hango-Zada: It’s all great, come on in, it’s nice and cozy over here at Shippit HQ.

So, I’d like both of these retailers to introduce themselves. I’m sure you’ve heard about them before, they’re quite prolific in the eComm space. And, I really want them to kind of inspire those that have joined the call and really help empower everybody that’s joined the call today.

Sandradee Makejev: So St. Frock’s started out at Bondi markets just over eight years ago. It used to be a little bit market store, and then we had the dust storm in Sydney, so I thought maybe I should start retailing online. A few experiments later, I was doing really well, so I quit my PR marketing job, and then I was just selling online. We opened a store that did well, we relaunched the site, and that was great because it helped increase sales. But 2013 was a big year for us because there was only about five people that used to work at St. Frock to run the markets, the store, and online. We were making about, in the beginning of 2013, we were making only about $20,000/month online, which was quite small. We did a few things for advertising and we were able to have 2,400% growth in just under ten months, so we were making, like, half a million dollars by the end of the year. We had to find ourselves a warehouse, we had to teach ourselves about, I suppose just warehousing, shipping. It was like a massive learning curve, but we took that all in our stride, and then year on year we were growing 100% each year, which was also very challenging as well. So, and I know I mentioned 35 staff, but today we have 45 staff helping us around there in the high season, and then it drops back to about 35 in the low season.

I absolutely love it, I love the problem-solving, I love the challenges, I even love the craziness of it all. It’s not for everyone, but it’s been a fun ride.

Rob Hango-Zada: So that growth seemed to be, I guess would have kind of shocked you in the early days. I mean, how did you get from 2,400% growth? I mean, how did that happen?

Sandradee Makejev: I think when you are in it, I was working seven days a week at that time, so I was living and breathing it, and just taking it in my stride. And I suppose, I don’t know, just wanting to, like, I knew that we were going to be expanding, and I just kept setting things up as I land, so I was always thinking about the future, as almost building and doing, my whole process.

Rob Hango-Zada: That’s amazing. And I guess now it’s sustaining and running this massive sort of business, an office full of 35 or 45 people. I mean I can imagine your challenges are a little bit different these days than what they were when you were at Bondi markets.

Sandradee Makejev: Definitely. The Bondi market, that was just me and one other staff member. But today I work with an amazing team of women and a few men, and I think, as you grow as a boss, I was very green back then, so I used to do everything myself. But now I work with an amazing team that each person is empowered to run their department, and they do it so well. I’m just amazed.

Rob Hango-Zada: That’s fantastic. Well done. And then it brings us to Nick from GoLights, so tell us about the story.

Nick Nicolaou: So our story is not too dissimilar as Sandradee’s. We started the business at the back of a family backyard. We would do five and ten orders, we had an eBay store. At that point we decided to launch GoLights, have our own website. We graduate to sharing a warehouse with a roofing company, with a room not too much bigger than this. You all can’t see but it was pretty small. So you know we experienced very rapid growth. We had to teach ourselves everything, whether it had to do with shipping, or marketing, technology, customer experience, even lighting. I mean, we weren’t really in the lighting space previous to starting this business. So, very steep learning curve, and we had to learn, what, you know, I think Rob mentioned something about building a plane while you’re flying it. It actually feels that way. So we kind of progressed, and the business kept doubling every year, and we kept trying to find ways to grow, but also just to take that growth and not having any experience running a business of that size, you know, most small businesses fall into this kind of abyss of doubting yourself, not really backing yourself to do certain things. You start looking for experts around you to help, you ask advice, you meet other people in the industry. And we did that fairly early on, and at that point we decided that we needed to look at how we could streamline our processes, and one of the things that we decided to look at first was warehouse operations, what we were good at, what we were bad at, and what we should do with it. So I’ll leave the introduction, then we can move on to some of the juicy stuff.

Rob Hango-Zada: So you mentioned that, somewhere in that mix, that you didn’t know much about lights at the time, so you had to learn that in addition to everything else.

Nick Nicolaou: Yeah, that’s right. We wanted to be in the eCommerce space, we wanted to be in the importing game, just for some macro reasons that we thought made sense to try and leverage ourselves to those two areas, and then the product became the third piece of the puzzle. We looked around at different categories, and we liked the lighting space, construction was booming, people became very power consumption-focused, and the increase in power costs. So in any event, one of our co-founders is an electrician. By trade, he had some insight into the lighting category, so we chose lighting, and yeah, we all kind of learnt as we went, and became experts in the product, which I think you need to be to be successful. If you don’t know your product, you’re probably not going to get there in the end.

So the learning curve has been very steep in many categories, but especially in the product category.

Rob Hango-Zada: Amazing.

Sandradee Makejev: Well done.

Rob Hango-Zada: Thank you for sharing that. And look, I’m really honoured to be in the company of two amazing business owners and entrepreneurs. So let’s kick in to it.

The Decision For 3PL

So you’ve both experienced a quite significant growth earlier on in your journeys. You obviously both didn’t have a logistics background, and really the eCommerce background. So let’s sort of start with the first question, I mean, why the decision to outsource fulfilment at that stage, and can you run us through that, maybe Sandradee can kick us off?

Sandradee Makejev: Yeah, sure. The big thing for us was that we were growing 100% year on year, we were worried about the scalability. I’m also worried about the costs involved as the, like, doing it in-house ourselves originally. Basically we thought if we could outsource, we could focus on our core competencies and create the business domestically and globally. We thought that using a 3PL would be more efficient and improve our customer experience. When we thought we could save costs on shipping, warehousing, and staff, we also thought that international shipping would be more cost-effective and seamless, and basically we were running out of space.

Rob Hango-Zada: Yup, and did you find that you guys were looking for similar things? I mean, was cost really important for you guys at that point? Were you looking at improving customer experience, or what was that prompted you guys to look at 3PLs?

Nick Nicolaou: Rob, all of the above. Al of the above. For us, one of the main considerations was we had strategy that we were going to roll out over the next few years. And one of those strategies involved possibly setting up a showroom to be able to showcase that lighting. We were getting started importing some of our own products in the decorative lights space, and we felt that if we had a physical location, even just a boutique showroom that could drive sales online, and get the brand out there.

As a result of that strategy, we had decisions make in… we’ve run out of space in renting a warehouse in Botany in Sydney, which was about 300 square meters office and warehouse, two levels, and we didn’t have any space to put the stock that we were importing. The goods were somewhat bulky, so that became a very critical point to consider. Furthermore, our lease was running out and we had to make the move, so we made the decision to outsource a warehouse operation to allow us to lease a property where we could have our office and our showroom. It was very difficult, especially in the Eastern suburbs of Sydney to find a property where we could have a showroom, a warehouse that was big enough, and office space in the same place.

So for us it was either-or type decision, and we thought, we’ll outsource to a 3PL warehouse operation, for the reasons that we all discussed and focus on rolling out a showroom and putting our team into a nice office space. So we kind of felt like we were in a situation where we needed to make… We were at a crossroads for the business. Strategically we thought it was a good play, and we did a lot of research, we became students of business, and business models, read tons of books, and I believe in the school of thought that you should always outsource to experts. You cannot be an expert in everything you do, and that is the way to scale your business. That still holds true and we still believe that. So ultimately that’s why we made the decision to move to a 3PL.

Rob Hango-Zada: Great. So you mentioned something there in the Sydney house crisis, or Sydney property crisis, all that sort of stuff, so I think that’s big enough for most people, but, yeah. So if I can summarise what we just heard is, obviously it’s sustaining the growth, momentum, and kind of staring back at the boxes that are staring you back, the poles and dresses, and it’s kind of one of the bases that prompts the need to change in operation. Obviously, to save some time and really focus on what we’re good at lead the logistics back to the experts as well. And obviously, one thing that I’ve picked up from Sandradee was something around speed and agility as well, so that you can focus on your core, sort of, business core priorities. Getting the showroom, in Nick’s case, focusing on the product mix, doing your buying trips, all those sorts of things.

3PL Incompatibility

So I guess what I want to understand is, did it suit your business? So obviously, it worked well for lots of businesses, but in some cases it doesn’t work out. I mean how did it work for you guys, and did it suit your business? So maybe let’s start with Sandradee.

Sandradee Makejev: Well, it quickly came to light that it didn’t suit our business, and there’s nothing wrong with that, it is what it is. And then we had to start to really think about what we’re going to do, like, because we exhausted a lot of avenues in trying to make the partnership work with the 3PL, and we had to make that hard choice at the end to bring it back in-house.

Nick Nicolaou: For us, and again, we did look at this very closely. The thesis for us was it was going to be faster, cheaper, less hassle, and more accurate. We’d never run a warehouse before, so we assumed that by outsourcing it we would achieve those four outcomes.

What actually happened was the opposite, and it’s because it didn’t actually suit our business. We were on a somewhat of a hybrid model where we import some of our own product. We buy and resell product from other lighting wholesalers around Australia. And we also use some supplies that dropship product for us. So that comes with its own technological challenges in terms of routing orders to and from, specifically with the warehouse situation, we had somewhere between 10 and 15 deliveries coming in everyday from different suppliers. These are lighting suppliers, they’re not very technologically efficient, so there’s always holes, and that’s basically holes, that’s the space we’re in and other businesses face the same kind of challenges.

For us what we actually needed was a very agile, robust, flexible warehousing solution to deal with all these issues coming in everyday with all these deliveries. The wrong colour was sent, the wrong globe, the wrong size–these scenarios show up a dozen times a day, and you need to be able to move quickly. Because of our model, whereby if you buy something on our website, we’ll have it delivered from a supplier the next day, and then ship it to out customer, our customer’s already been waiting one or two, sometimes three or four days, so we really have no margin for error once these deliveries show up. So a critical point for us was to get these deliveries inbounded and dispatched right away, so our customers need not wait any longer.

Now that actually conflicts greatly with the way that most 3PLs work, and we worked with two separate 3PL companies, and that’s a long story, but it was the same with both. Essentially, what they try and do is they work towards efficiency. They don’t work towards the customer experience that Rob touched on earlier. And when we have a delivery coming in and there’s some issues with it, the efficient play is to leave the issue alone, put it to the side, and work on everything that doesn’t have an issue. Doing that makes sense, but what happens is the customer that’s waiting for that order for that one product that’s now been put in to the corner to be dealt with at a later date, they’re waiting. And now our customer service team is being bombarded with a call.

So, a long way of saying, “No, it didn’t suit our business,” because there were some nuances, and got some permutations in the workflow that was required because of our model, but the 3PL operators could not handle.

If I didn’t have another 30 customers to deal with, sure, they could handle it, they’re much better at warehousing than we are. But that’s not the case, right? They’re a business, they deal with other clients, and they try and build a solution that does most of what you want for most of their customers. It isn’t customised to our business. And ultimately that’s where we kind of… That’s the mistake that we made in not understanding that. The battle is won around the edges, and it wasn’t efficient. So, yeah, it didn’t suit our business for those reasons, and there are some more specifics that we can go into in regards to cost. We like the idea of variable storage rates, we liked the idea of only paying for the storage that we use, but as far as I’m concerned, that’s a myth. And the reason for that is this: on Day 1 you go in there with 300 pallets, it’s great. A week later you ship, let’s say 20% of your stock, but you still get billed for 300 pallets. Why? Because it takes time, energy, and money to consolidate those pallets. So what we’ve found is, as we get picked with the pallets unconsolidated because that’s not priced into their pricing model. You pay per pick, you pay per order. There’s no consideration for, “Oh, we need to consolidate these pallets.” So in any event, what we found is variable storage rates didn’t help us. We found our source of pain is the same amount, regardless of how much stock we shipped out. In fact, we had staff at both 3PLs doing these for us, which cost us money. So in the end, we ended up taking the same amount as we would have if we had our own space. So that’s one tangible example.

Another example where a 3PL didn’t suit us is, we’ve got 15,000 products. Some of them are globes, some of them are one-meter-long chandeliers. We found that it was very cost-effective for us to package products in a certain way to take advantage of our dead weight due to the Australia post, where we only pay for the per kilo rate, so we could package together a few different boxes that didn’t weigh too much and save a lot of money. Again, that doesn’t fit in with the 3PL workflow. They make a margin on the freight, they make a margin on picking an order, they don’t make a margin on consolidating your shipment so that you can save money. And you don’t begrudge them for it, that’s just the model that you signed up for. So we found that it didn’t suit our business for that reason as well, when we could reduce our freight costs greatly by utilising that strategy. And that was for our business. Doesn’t really apply to fashion, I don’t think. So those are a couple of tangible reasons why it didn’t suit our business.

Rob Hango-Zada: Thank you for sharing that, Nick. You’re right, there are some nuances and complexities around your business that would really be a challenge for any third party logistics providers to even be able to modify their business to service without adding costs to their own business as well. I guess the complexity of lighting, I’d imagine, Sandradee, in fashion…

Sandradee Makejev: Very similar experience to Nick, especially things like the way that we used to package our items to lower the weights and size as well, so we could get cheaper shipping, or like combining things. It’s a very, very similar experience.

Rob Hango-Zada: I imagine there’s quite a few SKUs coming and going when it comes to seasonal fashion items as well.

Sandradee Makejev: Yeah, well basically, we get all of our fast fashion styles in, and then we pretty much have to clear them by the end of the season. That’s like new stock every season.

Nick Nicolaou: Some other challenges that we had as well revolved around, you mentioned SKU complexity. Some of our SKUs can be 20 characters long, so it takes a lot of time and attention to detail to actually get that inbounding and dispatch correct.

Another reason it didn’t suit our business is you’re restricted by the hours of 3PL operators. And this is very important, and it was lost to us at the beginning, but became very apparent as we got more involved. So when you’re really busy, and you’ve got a backlog, what I would do is get down to my warehouse, pack some models, and get them out. I’d come in on a Saturday, do the same. Come in on a Sunday, and do the same. You can’t do that when someone else runs your warehouse. And they don’t pack on weekends, obviously they tend to be more expensive, but most of them don’t. If there’s a backlog, you just have to live with it, and you move on to the next day and hope to clear the backlog.

So we were in situations, especially when we moved into these 3PLs, where we couldn’t get an order out for a couple of weeks while they got set up. And in the world of eCommerce, that’s just disastrous to not be able to do that. And the frustration kicks in, when it’s as simple as, “Can’t we go down there and pick the order ourselves?” No, for all the other reasons that involve insurance, and OHS etc. So we found we were restricted by their workflows, their regulations. When we did it ourselves, we didn’t have those problems. The team came in and we just dug in there and we got things done. And in business, nothing always goes the way that you plan it to, so you need to have a contingency for what happens when it goes wrong. Doing nothing is just not a strategy, and waiting for Monday to roll around.

So I think I just wanted to add those couple examples.

The Case For In-Sourcing

Rob Hango-Zada: Ok, fantastic. So I guess just with time in mind, we’ll just flick through a few more of the slides and get to the other detail but I guess we have heard a lot about the complexities, the key risks and challenges. You’ve got a big business, it’s growing, there’s lots going on, even more so now than probably what was going on before you outsourced your warehouse. So why on earth the decision to bring it back?

Sandradee Makejev: I think the biggest decision for us to bring it back was that we wanted complete control over our customer experience and our business processes again. We didn’t feel that with our 3PL we were able to…we felt helpless, quite helpless a lot of the time. So it was really important for us to bring it back because at the end of the day no one is going to care as much about your business as you do. As Nick said, putting in those extra hours before 9am, or after 5pm, or on the weekend, no one will care as much as you do.

There’s a few things, like the company was failing their KPIs, we lost thousands of customers over a four-month period, our phones were non-stop ringing, four lines at a time, we had to increase our own customer service team which we were still retained, threefold, just to cope. So it was a very stressful and disruptive time for my business. Resolution times were, instead of a few hours to fix a customer problem, it was days, weeks, or things never got resolved and I had to refund customers. My refund rate increased 57% and things like we were in a chokehold, because there were long lead times to receive stock.

Fast fashion, you’ve got to put up new stock all the time, new styles, you’ve got to remain relevant, you’re got to remain fashionable, its like churn and burn. So long lead times to receive in stock, which would take us a few hours, would take them over a week, so we were losing customers as well, because there wasn’t enough new stuff to shop from. Things like trying to get stock transferred to our boutique, it just never happened or it was wrong so our boutique stuff hurt a lot with sales and probably one of the big things at the end we had to seize international shipping.

We had been growing that organically for quite a long time over the years and we were doing quite well, we had 300 international orders a week, and that was without trying. So having to seize international shipping for several months was quite hard, and probably the staff morale, that was really hard as well. Staff were stressed, we felt helpless, so we were like, let’s bring it back, let’s take control, we can fix this, we can win back those people. If we have control we can fix those processes and get back to business.

Rob Hango-Zada: Got it. So I guess there’s a whole variety of reasons in there but predominantly it’s about bringing back control and being able to intervene personally is key, right Nick, would you share that?

Nick Nicolaou: Yes, very similar, I would answer the question in a couple of words, why we made the decision to bring it back. We didn’t have a choice. We would have folded. That’s the plain and honest answer, and there’s a lot of reasons for that, most of which Sandradee touched on. Our refund rate tripled, so that affects cash flow, in a disastrous way, especially when you’re in a capital intensive industry like us where we are importing some of our own stock which is quite expensive.

So our customer experience rating went from 97% to 85%. 85% is a pretty high number, but it’s pretty bad when you’re talking about customer experience, if you’re pissing off 15% of your customers and they are all going on Facebook or online, writing bad things about you and your staff, you’re just not going to survive too much longer. So for us we had no choice, we had to bring back the warehouse, and as Sandradee said, being in control of the customer experience, and being in control of our own destiny is very very important. One of the things that we didn’t consider when we went to a 3PL was what happens we you have a dispute with your partner. In most instances the customer has the power.

You’re in a dispute with someone, you don’t like what’s happening, you walk out the door, and business is over. Unfortunately with a 3PL you can’t really do that because they’ve got your stock, and that puts you in a very vulnerable position when it comes time to negotiate during disputes. Disputes happen every day in every business, we all live with it, we deal with it, you negotiate through it. Very, very difficult to do that when a company has your stock. You can’t get orders out, and at that point you need to make a concession, just to ensure that the business continues. So the risk of that for me is the biggest downside and the biggest risk to outsourcing any core competency, could be marketing, could be your customer service, it doesn’t matter what it is, for us, if we weren’t in control of our warehouse, and we didn’t have the ability to go in there and fix issues ourselves, we were not willing to bear that risk any longer.

How They Did It

Nick Nicolaou: Ultimately we put a plan together and we moved. We moved fairly quickly and we brought it in house. We bought a building, in Sydney, which isn’t too fun. But that’s just what we had to do, I was very fortunate to have a Co-Founder in Vince Hansimikali who we kind of sat down with, and we talked about it we just said let’s pony up a ton of money and go buy our own building so we don’t have to deal with this again. Also need to mention our team, our staff, they kind of went through a lot and they’re still with us. That’s how you get through it, you just come together as a team and you move on. So ultimately we just had to do it to keep the business afloat.

Rob Hango-Zada: So importantly, so how do you bring it back?

Sandradee Makejev: One of the key things like if you’re in this situation where you need or want to bring it back in house, or even if you’re considering using a 3PL, I actually hired a 3PL consultant, which was great for me because I only had my experience, up until I moved to a 3PL, then had the experience of the 3PL, in which I needed to bring it back in house.

So having that 3PL consultant just prepared me for like all the different scenarios that could happen, from good to bad, so when I went into the situation to terminate, to move, to organize the whole thing, make it fit back into my warehouse. I had someone there that was able to guide me through the whole process and give me confidence, and also prepare me for whatever may happen.

Rob Hango-Zada: What about I mean, obviously then shifting into your own warehouse, what types of tools, what type of processes, I mean how did you do that whole piece?

Sandradee Makejev: One of the main things, and not to promote Shippit, but Shippit was very instrumental in helping us move back. Very seamless, easy, no-fuss, it was actually the one thing that I didn’t really have to worry about when transitioning back in house. I was able to focus my whole energy on how I was going to move from one warehouse back into another one. Just basically setting up a whole new side to the business again. But that was great because we were able to set it up better than ever.

Rob Hango-Zada: That’s great to hear.

The Result

Nick Nicolaou: Yeah, like I said we bought a building and we just decided to bring all our stock back, set it up, in an inefficient way, because we’re not experts at warehousing. We definitely don’t do it in a way that… we don’t do it in a way that is very scalable, but at least we get it done. We will deal with the problems as they arise. Shippit was also instrumental for us, it just helped integrate very seamlessly into, we use Magento so we were fortunate they had already built that integration and it allowed us to use a variety of carriers.

We’ve actually been able to decrease our freight costs greatly, on account of the Shippit platform. We’ve got some of our own freight deals which was very good, but Rob and the team have done a good job of bringing onto the team some quality partners. We found out freight costs decreasing drastically. When we first moved which was about 10 months ago, but also in the last few months with some of the work they’ve been doing, bringing on new partners. So essentially what we did is rip the band-aid off and we didn’t hire a consultant, which I wish we did. Because it would have been a little bit easier, but we got there and now our warehouse is doing more orders than we ever did, our dispatch rates have dropped, our refund rates have dropped, our customer satisfaction has increased.

And we’re still not very good at it, but at least we’re in control of our own destiny and we’ll become great at it, like every other aspect of the business we have taught ourselves. So we got back to our growth, we actually grew 77% in the year that we were in 3PLs, despite all the issues. We made the BRW Fast Starter’s List, so the team’s much happier, and everyone, everyone is happy and focused on the way things are going. So yeah, that’s essentially how we brought everything back, and that’s what the results have been so far.

Rob Hango-Zada: That’s very well done guys. It couldn’t have been easy, the whole piece, but to really be empowered enough to run your own operation is no mean feat. So tremendous job to both of you. So I guess Sandradee, how were the results for you, how did that turn out?

Sandradee Makejev: Well basically just having greater control over the customer experience, and that was really exciting for our team, because it was so stressed for such a long period of time, that everyone was all in, arms, legs, tongues, everything, because they wanted to see the business succeed. We’d had such a great journey, up until outsourcing it, that everybody just wanted to succeed again. So we were able to knuckle down, we improved our costs for warehousing, shipping, staff, our customer satisfaction has never been higher, our pick accuracy have never been higher.

We’re on track to grow another 120% this year, which is massive considering we’ve had negative growth of 20% the prior year, which is quite upsetting when we had always been growing 100%. We were able to re-launch international shipping, same-day delivery, a whole bunch of cool stuff. We wanted the big things to me, I was determined to win back those customers we had lost, so we did like a win back campaign where we managed to re-activate 30% of those customers, and 50% of them are repeat purchasing, so it’s all down to the hard work of the team. Obviously it’s my business, but I’ve got some amazing, amazing women that just really wanted to see Go Lights get back to previous success levels.

Rob Hango-Zada: Amazing guys, well done.

Nick Nicolaou: Our combined costs for freight, fulfilment, warehousing, including your rents and all this was about 15% from when were at the 3PLs, we’re currently 8.5%. So that’s significant when you’re thinking about financials, when you’re thinking about cash flow, profitability, how do you grow the business? Well, you need to be profitable to do it. So that’s been very important for us, being able to get our costs back under control so we can fund all our growth strategies.

Tips For Nailing 3PL

Rob Hango-Zada: Amazing. Well I know we’re tight on time, if you could finish just on tips and tricks on how to do 3PL right. Obviously, it’s a tricky balance for all, but if you could just summarise the top tips in how to choose the right 3PL partner, if that’s the right solution for your business, and then what we can do is throw questions back to the audience. Sorry we’re running a bit behind schedule, but hopefully we can cover these off, because I think these are really important too.

Sandradee Makejev: Basically, do the clients have the same kind of products and business size as me? That’s really important, have a look at their other clients, sometimes it’s great to be with a specialised 3PL, versus someone who has mixed different businesses. Can they handle the order volume and the varying demands of multiple clients? That was probably a big mistake for me because there we so many different kinds of businesses that had varying demands, that it meant that I only got a small part of their customer service team, and it felt like I got pushed to the back of the queue a lot.

My problems were really severe, like our order levels would come up during our busiest season. I was helpless to actually get anything done. Can they handle complex SKUs? How do they conduct their rolling stock take? A big thing if I ever considered a 3PL again would be, I would want a list of all the clients, and I want to check their Google reviews and social media accounts, I don’t just want the standard three references, I want to see what the customers are saying about their business, because that’s going to be a true indicator for me. Is it working well for all these other clients? What expectations does your customer have for delivery and do they align with their other clients, and for that business.

For fast fashion, we have to get it out within a few hours, or it has to be to the customer within 24 hours. We need to compete against iconic, all the other online stores, that’s super important to me. A clear indication of monthly admin, receiving in time frames and hourly costs, because they can blow out. Make sure you get an itemized account of all charges each month, and question them, don’t be afraid to. Probably the last thing would be to get quotes from different 3PLs, compare price, process and make sure you understand it.

Nick Nicolaou: Yeah, I’d add a couple of things to that. I think getting a list of their current clients and checking the clients, the customer’s Facebook and other social media platforms is imperative because you can’t hide that. If someone is at a 3PL and they are not doing a good job, their customers are going to tell everybody.

Sandradee Makejev: And Google reviews. You can’t delete those, they are there forever.

Nick Nicolaou: So that, I would put that right at the top of the list, because it’s fairly easy to do and no one can fake it. I would also say just a point on when considering 3PL. For us, we were under duress when considering 3PL, it was a rush decision. We felt like we had to make a move, you’re growing a business and you’re looking at different ways to do it. So I feel like most people are in that frame of mind, when they’re considering 3PL, doubting themselves, or we can’t do it as good as these guys.

So I feel like we end up drinking the Kool Aid, of all the different stats that people put in front of you, and all the different strategies that they employ, so I think what I would say is: Don’t be rushed, don’t feel like you’re not doing it well enough, and that you are forced to go and get some experts involved. Take your time, really look at the problem, don’t make a decision under duress. And I think most people, for us, if we weren’t under duress, we probably wouldn’t have made the mistake.

I would also add that you should test them. I realise that it’s no fun running shipping from two locations, and it’s hard with tech, and it’s hard with a few other things, but it’s just so important, it’s a core competency. I would test them for 3 months, give them a certain set of SKUs, a certain set of orders, and just stress-test their systems. Again, once you’re actually in play, there’s nowhere to hide, all the inefficiencies and all the conflict, and all the areas where it may not suit your business come to light, and then you can make a decision whether you want to solve them or whether you want to abort the operation, that’s not an easy thing to do.

I would also add that having lawyers go over the contracts, and being very clear about obligations and expectations when exiting. Exiting for us, especially in one of the instances, was an absolute nightmare, where we needed to go legal, and at the end of the day when someone’s got the stock and you’re looking at contracts and the lawyers want to negotiate, it’s irrelevant, because the stock’s not getting out, your orders aren’t getting out, so good luck trying to fight it. You can fight it but you won’t, because you can’t wait 6 weeks and not ship an order. But I would get some lawyers involved up front, go through the contract, add things to the contract, that gives you a very easy and seamless way out, in the event that you’re in dispute, and that happens, it doesn’t mean anyone did anything wrong, sometimes it just doesn’t work out, and you need to be able to get out in a very seamless way that doesn’t hurt your business.

Sandradee Makejev: And I think one more thing I just want to quickly add, make sure you have an exit plan if things don’t work out, to bring it back in house, have a think about what you would do if, it’s great to have all the ideas for moving into 3PL, but you also have to be well are about what would you have to do if you are going to bring it out.

Rob Hango-Zada: Thank you for sharing guys, we have a variety of 3PL partners ourselves, so if you are looking for advice, and you are looking for some further information, either from myself, Sandradee or Nick, please connect with us on LinkedIn. We’ll share this presentation out with the audience as well, but let’s flip to questions if we have time, if there’s any burning questions in the audience?

James Webber: We’re a bit short on time, there are a few questions that have come through the pipeline, and I think we can hopefully get back to people with those off-air because clearly we are five minutes over-run, I think it’s been a really interesting discussion and clearly Nick and Sandra have been through the mill on the whole logistics front and it’s not too dissimilar from something I have experienced, I think people talk about 3PLs or not being suitable for them.

I wonder at times whether the business is ready for a 3PL. Certainly I actually had a very good experience with a 3PL, but they were experts in my category, and they were very focused in the category. I think there would have been a time where I would also actually outgrown that 3PL and brought it back in house, due to the fact that my major competition was international eComm players therefore my major differentiation was speed of delivery, and in order to get that, that meant I needed to own that customer interface.

So I think there’s lots of reasons for doing one and the other, but the key thing is making sure your business is ready for a 3PL, and to do that you’ve got to really understand what they need from you and how you’re going to integrate those. All credit to you guys for going through that and coming out the other side, many don’t. Great learnings for everyone on this webinar. Please come back and send your questions in and we’ll try and get those answers back to you outside the webinar. Thank you, Rob, Sandra, Nick.

Rob Hango-Zada: Thank you, more details about us, the website, details are here, feel free to connect with us on LinkedIn, hope to speak to you soon. Thank you very much to Sandradee and Nick.

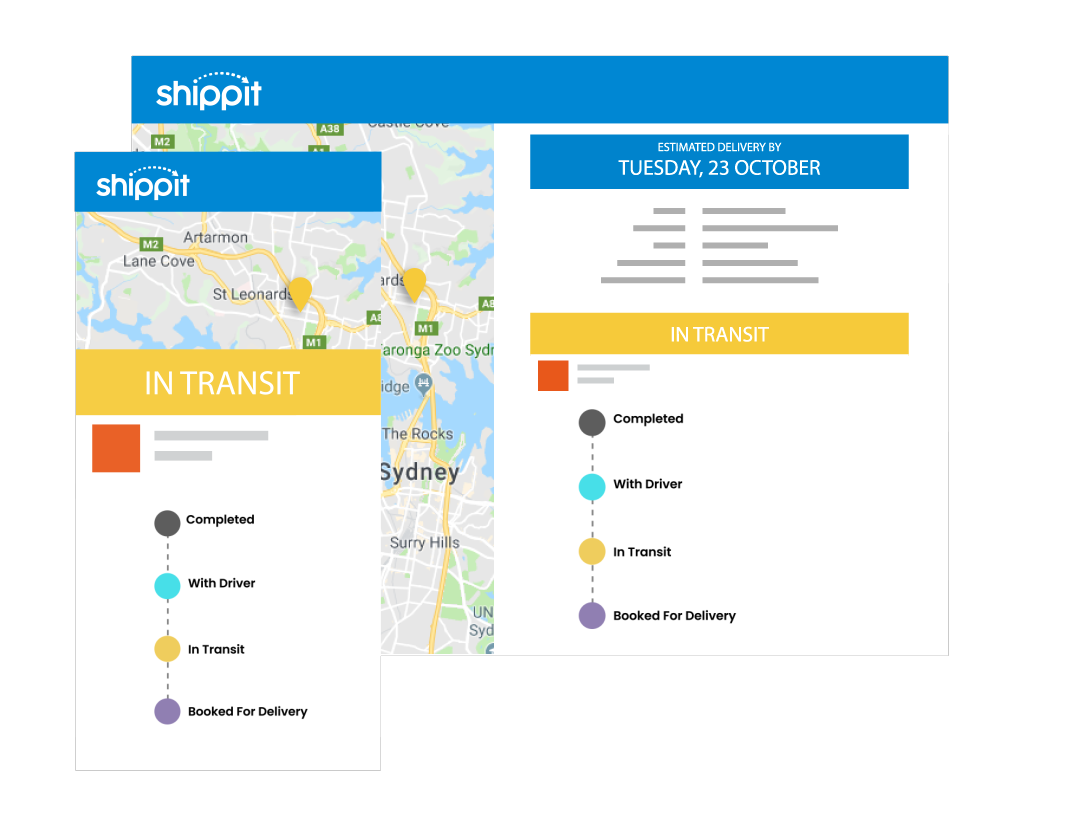

Shippit.com is the shipping engine for modern retail. Learn more about our how our software can save you time, money and keep your customers happy.